BDS Magnetic Core Drill Machines are the Epitome of Precision and Power in Metal Drilling. Crafted with Cutting-Edge Technology, These Machines are Designed to Navigate Through Metals with Unparalleled Accuracy. from Stainless Steel to Hardened Alloys, Bds Magnetic Core Drill Machines Effortlessly Cut Through, Providing a Seamless Drilling Experience.

-

Series Quick-In HSS-Co 8-F Annular Cutters

Ideal for quick-in recording system. 18 mm shaft for quick-in mounting system. 35 mm cutting depth. The made in Germany annular cutters from this series have outstanding heat resistance and wear protection. In combination with speed-controlled BDS magnetic core drilling machines, these annular cutters are suitable for machining fine-grained steels and rustproof materials. BDS recommends the BDS 5000 Cutting Oil for machining stainless steel

-

-

Shank Adaptors

DescriptionFor Core DrillsAdapter / Weldon 19 mm (3/4″) AdapterFeinAdapter / Weldon 19 mm (3/4″) AdapterUniversal

-

Shaving Collection System QBit UX SDS Shank

- With the aid of a high-efficiency vacuum collecting system with low drag, almost all of the generated dust and shavings can be vacuum extracted.

- With the aid of newly designed holes and cross-shaped tips, vacuum extraction has become more efficient.

- Adopting the new Q adapter with a spring enables it to be detached easily.

-

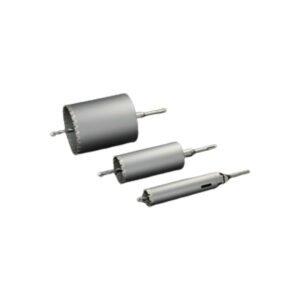

Single-function core drill bit E&S ALC Type

Single Function Core Drill E&S

- Compatible with ALC features. Large-bore drilling realized for hard-to-drill materials of ALC panels.

- Outstanding rotational force enables easy cutting of ALC panels including piano wires and double reinforcement.

- Sharp drilling force is provided for the ultra-hard tips of cutting edges. Adopts high-toughness materials that excel in wear resistance.

- SDS shanks are also available at the same price.

-

Single-function core drill bit E&S DC Type

- Capable of drilling reinforced concrete (cutting up to triple-reinforcement) by dry process without using water.

- Center pin positions only to reduce vibration and noise.

- Uses “10 mm/13 mm chuck combination shank(PAT.P)” allowing most drill chucks.

- SDS shanks are also available at the same price.

-

Single-function core drill bit E&S Multi-type

- Multi-purpose in drilling in siding board walls, plasterboard, FRP, veneer panels, PVC panels, and compound materials etc.

- Pocket shape in consideration of swarf discharge efficiency also facilitates smooth drilling in thick panels and deep holes.

- SDS shanks are also available at the same price.

-

Single-function core drill bit E&S RC Type

- Adopts a sharp cutting-edge shape which enables speedy drilling only by rotation.

- Simultaneous pursuit of accuracy and efficiency. Sure and steady drilling is enabled even for fragile work materials.

- Uses “10 mm/13 mm chuck combination shank(PAT.P)” allowing most drill chucks.

- SDS shanks are also available at the same price.

-

Single-function core drill bit E&S VC Type

Single-function core drill bit E&S VC

- Applying vibration and rotation to the cutting edge enables speedier drilling by crushing the work material while drilling.

- A wide lineup of diameter sizes of 22 mm to 220 mm.

- Uses “10 mm/13 mm chuck combination shank” allowing most drill chucks.

- SDS shanks are also available at the same price.

-

SKF 25

The SKF 25 Portable Beveling Machine also called as Manual Beveling Machine Delivers Wide Chamfers Up To 15 mm, Continuous Angle Adjustment From 15 To 60 Degree. The SKF 25 Beveling Machine Has Ergonomic Handle Arrangement, Easily Guided With Guide Rollers.

Good Work Preparation, Good Results – This Universal Plate Beveling Machine With Integrated Tube Enables Perfect Weld Preparation.Large Guide Rollers And A Continuous Angle Adjustment From 15 To 60° Render The System Practical.The New Hand-Guided BDS Machine Is Ideally Suited For Easy And Quick Preparation Of Welded Seams. On Account Of Its Low Weight Of 22 Kg, It Is Easy To Handle And Can Be Guided Exactly And Easily With Smooth-Running Rollers. The End Result Is Uniformly Milled Edges For Perfect Welded Seams.

The SKF 25 Beveling Machine Bevels 15° To 60° Angles On Plate Or Pipe With A Continuously Adjustable Angle And Land Width Up To 3/4″. Ideal For Use On Steel, Stainless Steel, Aluminum And Nonferrous Metals.

Offers High-Quality Performance That Allows For Superior Weld Connections. Robust Design, Single Operator Control And Easy Handling; Designed For Continuous Operation With Smooth Roller Guides.The SKF 25 Beveling Machine’s Anti-Vibration System Protects Electronics And Allows For More Comfortable Operation. Includes One Milling Head And 10 Indexable Inserts For Fast Metal Removal And Extended Tool Life.

Work On Welding Angles And Weld Preparation On Pipes/Tubes With A Minimum OD Of 6-1/4″ (160mm) With Built-In Pipe Roller Guide; Ideal For Beveling Pipe 6-1/4″ OD And Larger. Precise Roller Guidance, Low Friction Resistance. Single-Operator, Straightforward Handling.

The automatic feed beveling machine is available as model number AutoCUT 500 -

T.C.T. hole saw Cordless Meta-core

- A first in Japan! T.C.T. hole saw for use with rechargeable and small electric drills (under 400W). Enables drilling of stainless steel with low power.

- Cutting resistance cutting edges and center drills comprehensively reduced. Allow 3 times the number of hole drilling with a full charge (compared with standard Meta-core).

-

T.C.T. hole saw Meta-core

- T.C.T. hole saw standard type.

- Adopting the step center drill dampens impacts that occur when the center drill passes through.

- Adopting the “10 mm/13 mm chuck combination shank,” allows for most drill chuck diameters.